Capabilities

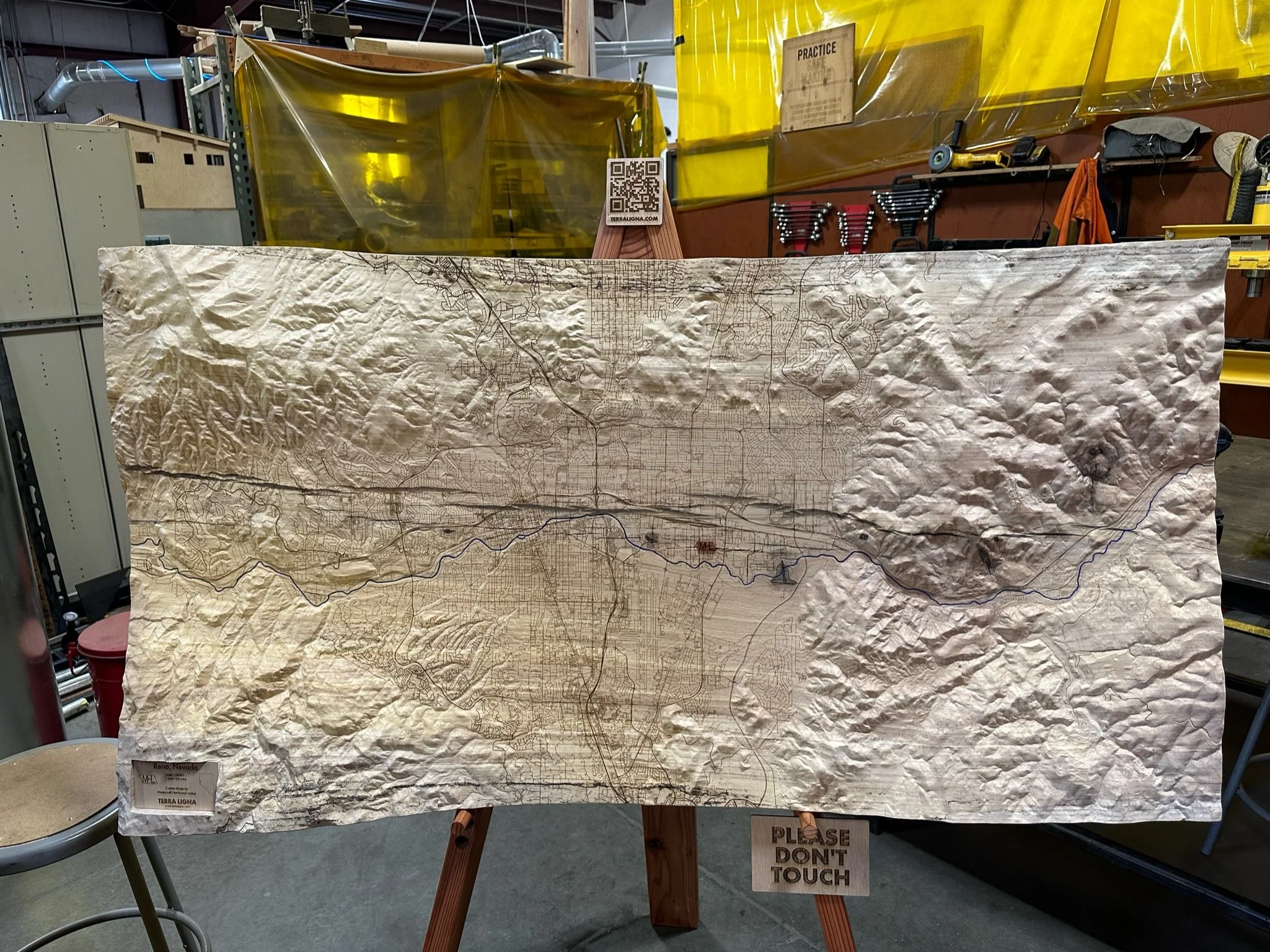

Our wooden maps begin as an idea. We start with digital elevation models (DEMs) of each client’s desired location that are derived from either orthophotogrammetry, or aerial and space-borne laser elevation measurement (LIDAR).

These are obtained at the highest possible spatial resolution from government sources and then seamlessly merged, reprojected, clipped, and mathematically manipulated with several different proprietary customized mapping and modeling algorithms and map projections to prepare them for three-dimensional modeling.

The DEMs are then converted to mesh in the form of a Triangulated Irregular Network (TIN), which itself is then converted into a 3D file that is typically on the order of 2-20 gigabytes, a process that sometimes takes a few days of background computing.

The resultant 3D model is then toolpathed and cut into one of several wood species on a computer controlled (CNC) router system with a suite of different router bits in successively smaller shapes over a period of about a week. Some carves take up to 7 days-worth of continual machining time.

Depending on the presentation, some maps are finished with laser-engraved cartographic labels and topographic details and information.

After machining, each piece is carefully sanded by hand and then sealed with all-natural oils, and either framed with hardwood or left unframed for our customers to frame. We use both laminated Baltic Birch plywood and solid custom-milled slabs of soft and hardwoods to create our maps.

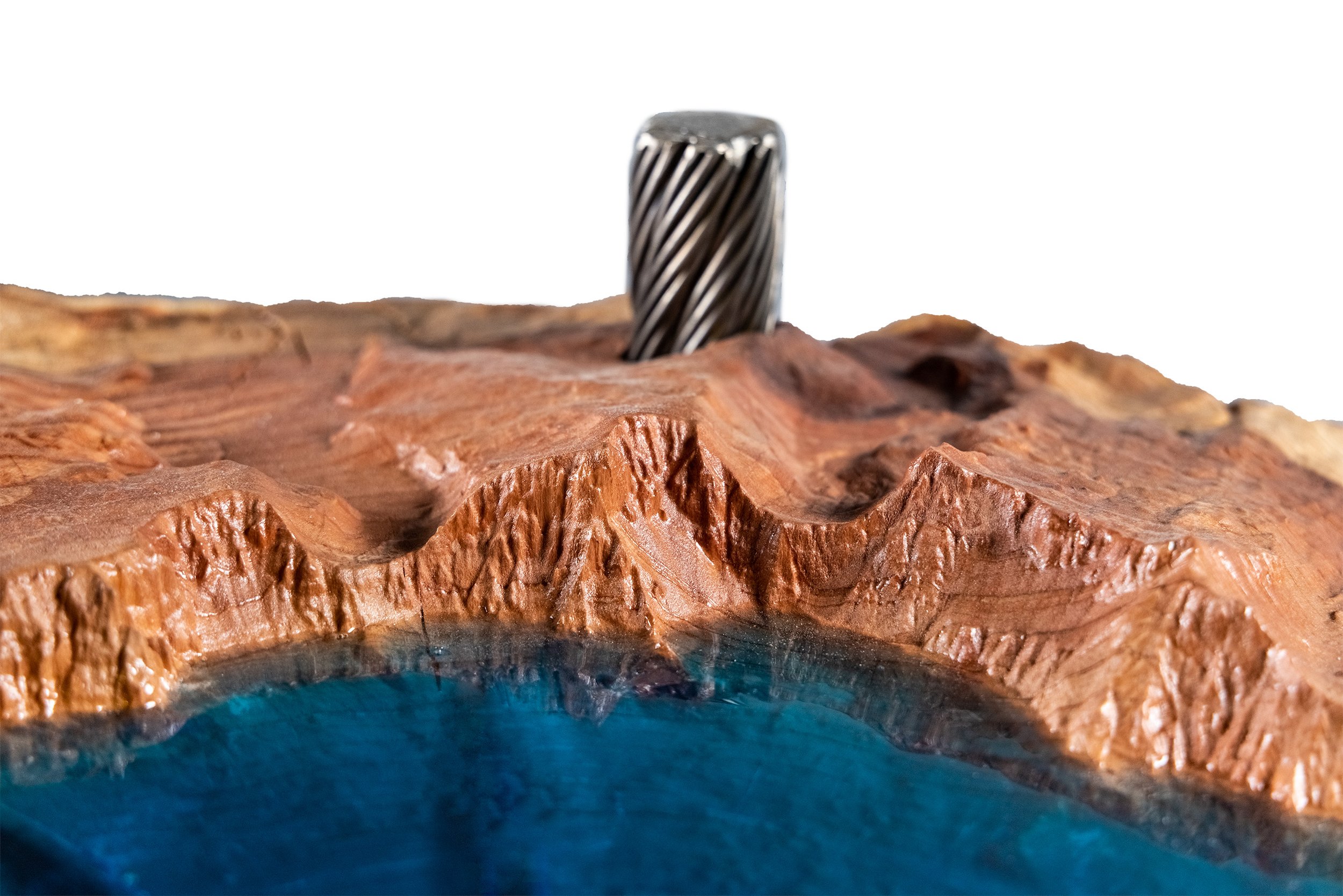

We also fabricate custom glass-topped map tables, some created with reclaimed chairlift steel haul rope or logging operation braided steel cable.

Accurate, Intricate, Detailed, Unique

Tahoe West Shore Backcountry Ski Map

Palisades Tahoe Coffee Table

Mt. Rainier

Mt. Rainier

Crater Lake in Redwood

Palisades Tahoe

Kaua'i Hawaii

Zion in Walnut

Little Cottonwood Canyon

Crater Lake Redwood